On 12th February 2020 the Daimler group honored its best suppliers for the twelfth time.

SaarGummi Group was among the winners and the only company who received the Daimler Supplier Award in the division Mercedes Benz Cars & Vans in the category "Quality".

CQLT SaarGummi Technologies S.à.r.l: Recognized for ensuring a smooth start of production through the management of necessary industrializations in the material group “Seals”.

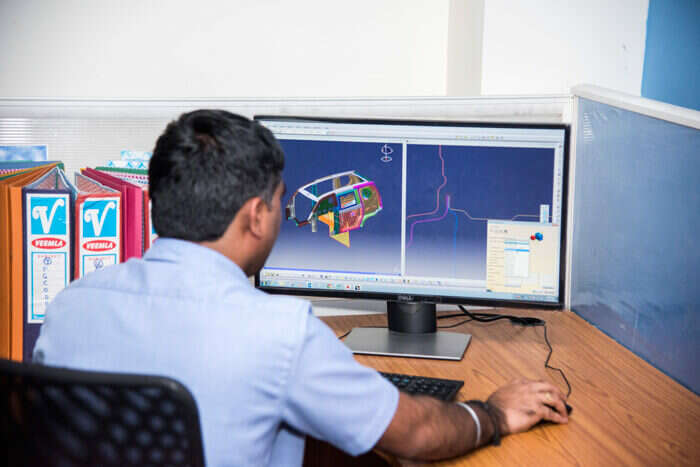

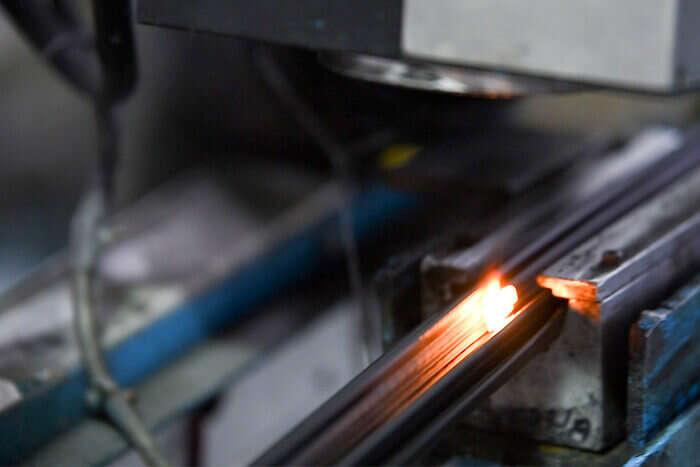

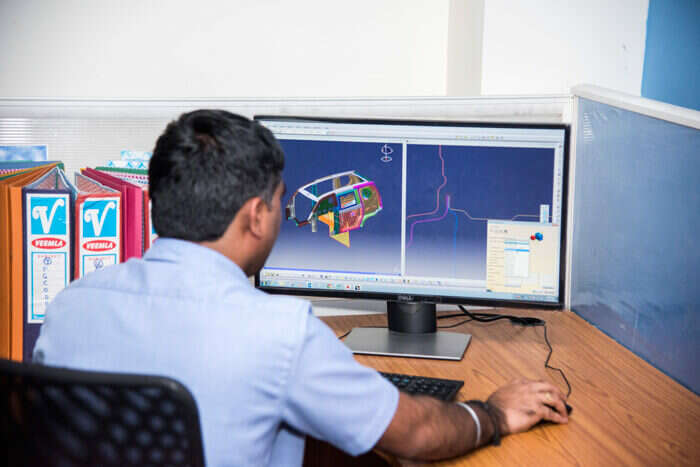

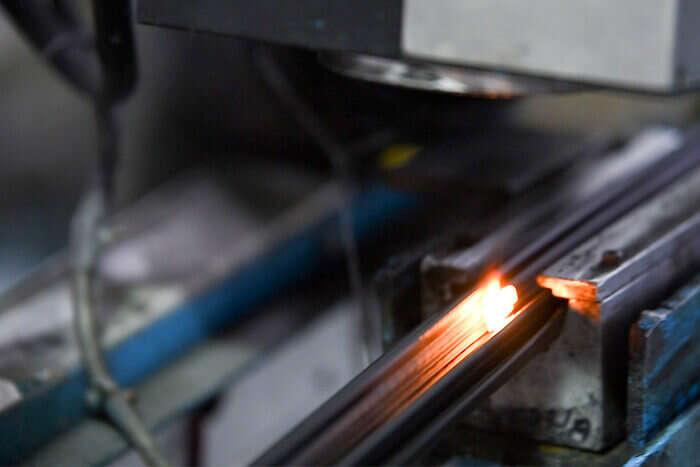

The facilities all the plants are IATF 16949:2016 & ISO 14001:2015 certified to ensure controlled processes to repeatedly deliver, technically sound and technically innovative products.

To meet the stringent technical specifications and SAARGUMMI Global Quality Standards, complete Inhouse Laboratory and Testing Facility have been set up in Daman, Ahmedabad and Chennai.

Every compound batch is tested for Critical To Quality (CTQ) properties.

All products undergo extensive validation and testing during the development phase to meet the high quality standard specifications of the OEM customers.

The same high standards are followed for all products including products manufactured for use in cabins of agricultural & earth moving equipment, medical equipment, and enclosures in industrial equipment.